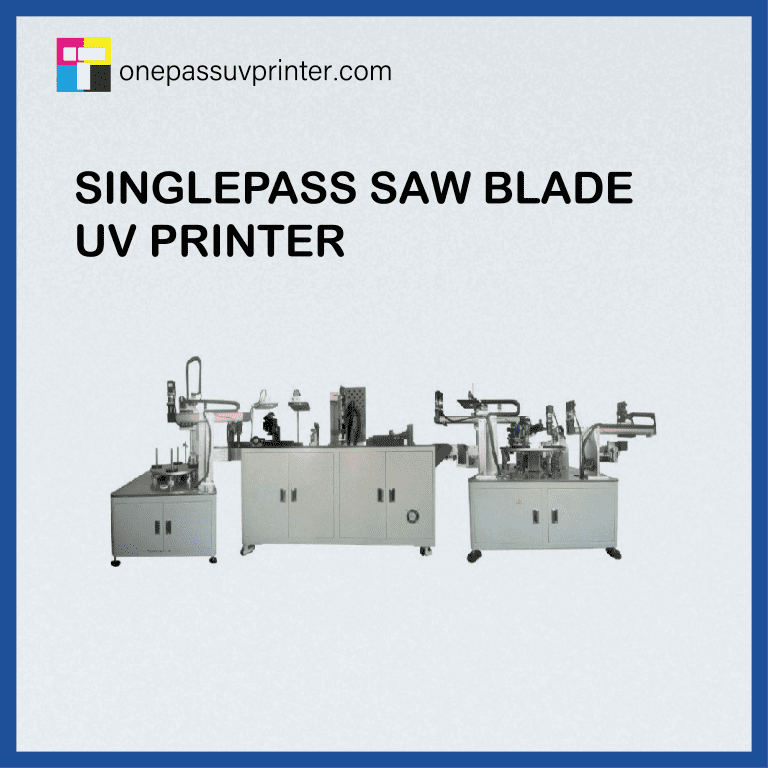

streamlined production flowcompact one pass printing module for kiosks bench top

Print production industry is being reshaped by pioneering one-pass UV developments. This innovative system allows rapid throughput with outstanding image quality and robustness. Employing immediate UV curing for inks and coatings, one-pass UV printing removes lengthy drying and multiple passes, materially cutting time and costs.One important advantage is creating colorful, resilient prints on an extensive array of substrates like plastics, metals, and textiles. The high resolution capabilities of one-pass UV printing result in stunningly detailed images and text, making it ideal for applications such as packaging, signage, and promotional materials. Furthermore, this eco-friendly technology utilizes lower energy consumption compared to traditional printing methods, contributing to a more sustainable production process.

Print production industry is being reshaped by pioneering one-pass UV developments. This innovative system allows rapid throughput with outstanding image quality and robustness. Employing immediate UV curing for inks and coatings, one-pass UV printing removes lengthy drying and multiple passes, materially cutting time and costs.One important advantage is creating colorful, resilient prints on an extensive array of substrates like plastics, metals, and textiles. The high resolution capabilities of one-pass UV printing result in stunningly detailed images and text, making it ideal for applications such as packaging, signage, and promotional materials. Furthermore, this eco-friendly technology utilizes lower energy consumption compared to traditional printing methods, contributing to a more sustainable production process. The integration of one-pass UV technology has opened up new possibilities for businesses seeking to enhance their printing operations.

The integration of one-pass UV technology has opened up new possibilities for businesses seeking to enhance their printing operations. UV Single-Pass: Revolutionizing Digital Printing

High-speed digital printing has always sought efficiency. Previously this demanded multiple ink cycles, adding time and alignment challenges. However, the rise of Single-Pass UV is upending traditional approaches. Using UV to cure inks in a single pass, the system delivers marked increases in throughput and exactness.With single-pass UV, colors appear vivid and crisply defined, offering extraordinary richness. This makes it ideal for demanding applications such as high-volume packaging, billboards, promotional materials, where speed and visual impact are paramount. With ongoing development, single-pass UV will likely bring additional innovations toward faster, flexible, and affordable production.

Elevating Print Production with Single-Pass UV Printers

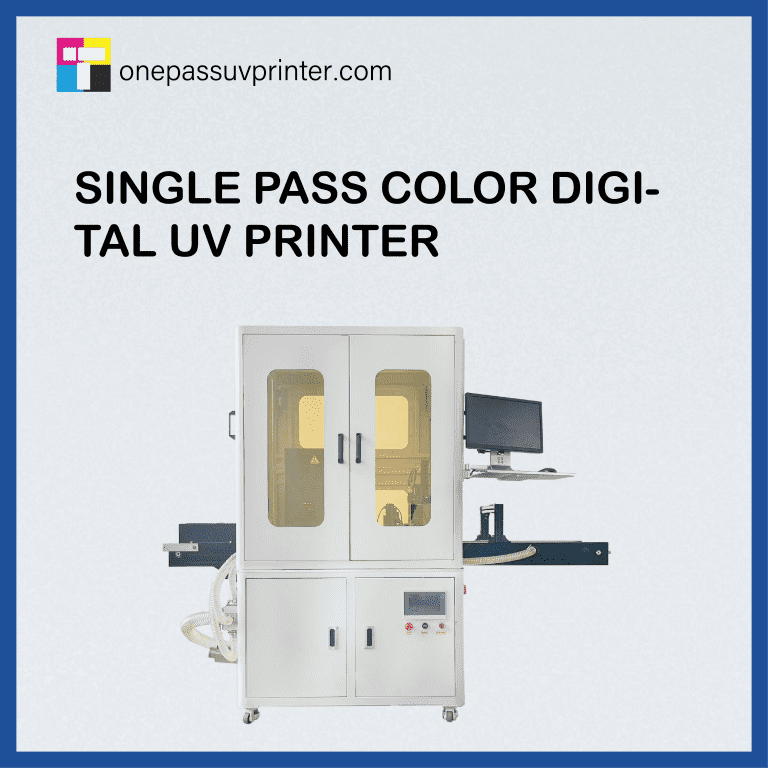

In modern printing tech, single-pass UV printers are revolutionizing how speed, precision, and efficiency are delivered. These machines utilize UV curing to harden inks at speed, facilitating exceptional production levels. By executing multiple colors in one pass, these printers produce exceptional clarity and vibrant color profiles. From custom short runs to mass commercial production, they support diverse applications, helping companies meet growing market needs.Elevate Your Printing Process

Be ready to be amazed by the single-pass UV printer — a breakthrough solution raising industry bars. This innovative unit uses UV light to cure inks on one pass, producing outstanding print definition and clarity.- Experience vibrant colors with unparalleled precision

- Amplify throughput via high-speed printing

- Expand new creative possibilities with a wide range of printable materials

Express UV Printing: Delivering Unmatched Efficiency

UV printing has upended traditional graphics workflows with greater speed, accuracy, and color vibrancy. Still, high-velocity UV printing amplifies those positives, driving extraordinary production efficiency. It employs specialized machines designed to generate high-resolution imagery rapidly. Due to immediate curing and short dry times, fast UV printing tightens workflows and supports meeting challenging order demands. The benefits of high-speed UV printing extend beyond mere efficiency. It delivers outstanding one pass printer image fidelity, robust durability, and many practical applications. From packaging and banners to labels, promos, and signage, high-speed UV is changing business workflows and enabling innovation, agility, and competitive advantage.

One-Pass Production: The Ultimate Solution for Fast Turnaround Times

In our rapid world, speed matters most. For print production, fast and efficient systems are essential. This is the promise of One-Pass Print. The system supports one-pass prints, eliminating repeat runs and reducing overall process time. One-Pass Print secures much faster delivery times, freeing valuable time and resources. Consequently, companies small and large gain from One-Pass Print benefits. From promotional pieces to critical documents, the tech enables timely printing without sacrificing quality.Quality and Velocity Combined in Single-Pass UV

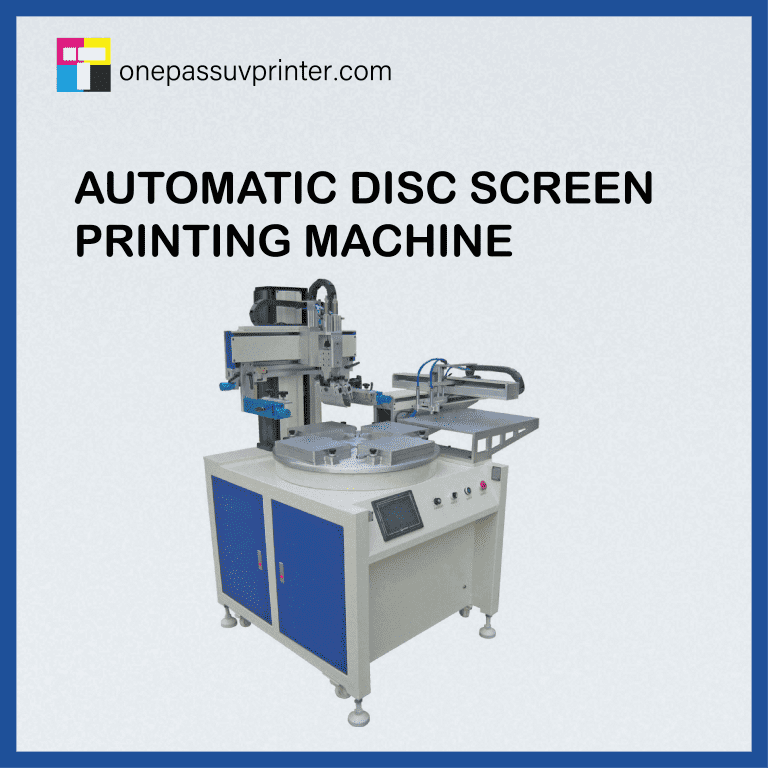

Within today’s manufacturing sector, efficiency stands as the cornerstone. Manufacturers demand workflows that balance top quality with rapid output. Single-pass UV surfaces as a pioneering solution tying high-quality inspection to quick curing. The approach uses UV-induced curing for inks and coatings to create lasting vibrant finishes and trim production time. Single-pass UV’s innate accuracy produces flawless results that satisfy stringent quality requirements. Advantages include broader operational and environmental improvements. Single-Pass UV trims waste levels by eliminating lengthy drying, contributing to greener manufacturing.- Furthermore, the broad applicability of single-pass UV spans packaging, printing, and electronics production.

Advancing Digital Printing via Rapid UV

The industry moves forward constantly, urged by ongoing needs for faster speeds, better precision, and inventive approaches. High-speed UV appears as a pivotal innovation that blends speed, precision, and adaptability. Instant UV curing in printing dispenses with lengthy drying and opens creative and commercial opportunities for printers. Fast UV cure produces high print rates, cutting production time and elevating operational efficiency. Also, UV inks offer resilience and resistance to fading, scratching, and water damage, ideal across many applications. From eye-catching displays to resilient packaging, high-speed UV is altering print workflows.- Gains

Instant Output Age: One-Pass UV Technology

In rapid-design and imaging contexts, time is extremely important. Clients seek rapid delivery, and businesses must offer high-quality prints swiftly. One-pass UV printers address this need by providing an innovative solution for modern printing. Advanced single-pass units use UV-based inks that cure on contact with light, removing drying delays. Resulting in instant prints with vivid colors and durable results. As a result, single-pass UV printers serve many industries and use cases. From retail and online commerce to marketing, photography, art, and manufacturing, enterprises adopt instant prints. Applications include creating custom items, producing tailored signage, and making eye-catching marketing collateral. Advantages include more than just faster turnaround and efficiency. Single-pass UV units also provide superb color fidelity, high resolution, and broad material compatibility for challenging projects.- Also, one-pass UV offers environmental benefits by not requiring harsh solvents or VOCs.

- To summarize, instant-print technology is established: with speed and versatility, one-pass UV is altering printing toward greater efficiency.

Enhance Workflow via Single-Pass UV

Streamline your production process and unlock new levels of efficiency with a single-pass UV printer. This state-of-the-art tech prints vivid, high-resolution imagery onto various substrates in a single pass, eliminating multi-layer workflows.- Realize superior speed and shorten production durations.

- Maximize your output with a faster turnaround time for orders.

- Take advantage of UV ink resilience and precision for lasting vivid output.

Single-Pass UV: A Game-Changer for High-Impact Printing

Single-pass UV printing stands out as a transformative approach to high-impact print. The technique applies ultraviolet curing for inks, offering notable improvements over legacy methods. Firstly, single-pass UV printing provides unparalleled image quality due to its ability to produce highly vibrant colors and crisp details. By removing drying stages, the cure boosts productivity and speeds turnaround times.- Also, prints from single-pass UV deliver long-lasting resistance to fade and abrasion.

- Summing up, superior image fidelity, productivity gains, and lasting prints make single-pass UV a compelling high-impact solution.